What is 3D Metal Printing

With the development of science and technology and the needs of popularization and application, the use of rapid prototyping to directly manufacture metal functional parts has become the main development direction of rapid prototyping. Currently, the main metal 3D printing processes that can be used to directly manufacture metal functional parts include: Selective Laser Sintering (SLS) technology, Direct Metal Laser Sintering (DMLS), Selective Laser Melting (SLM) technology, Laser Engineered Net Shaping (LENS) technology and Electron Beam Selective Melting (Electron Beam Selective Melting, EBSM) technology, etc.

1.Selective Laser Sintering (SLS)

Selective laser sintering, as the name implies, uses a liquid-phase sintering mechanism. During the forming process, the powder material is partially melted, and the powder particles retain their solid-phase cores and undergo subsequent solid-phase particle rearrangement and liquid-phase solidification. Bonding to achieve powder densification.

The principle and characteristics of SLS technology:

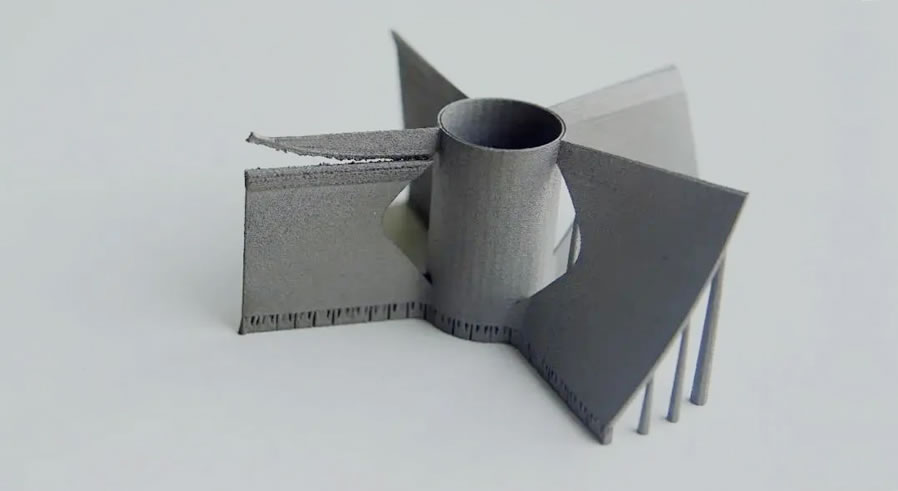

The whole process device consists of a powder cylinder and a forming cylinder. The piston of the working powder cylinder rises, and the powder spreading roller evenly spreads a layer of powder on the working piston. The computer controls the two-dimensional scanning trajectory of the laser beam according to the slicing model of the prototype. There are options. Solid powder material is sintered to form a layer of the part. After completing one layer, the working piston descends one layer thickness, the powder spreading system spreads new powder, and the laser beam is controlled to scan and sinter the new layer. This cycle repeats, layer by layer, until the three-dimensional part is formed.

The SLS process adopts a semi-solid liquid phase sintering mechanism, and the powder is not completely melted. Although the thermal stress accumulated by the forming material can be reduced to a certain extent, the formed parts contain unmelted solid phase particles, which directly lead to high porosity and density. Low, poor tensile strength, high surface roughness, high process defects, in the SLS semi-solid forming system, the viscosity of the solid-liquid mixed system is usually high, resulting in poor fluidity of the molten material, and there will be metallurgical defects unique to the SLS rapid prototyping process – ” spheroidization” effect. The spheroidization phenomenon not only increases the surface roughness of the formed parts, but also makes it difficult for the powder spreading device to evenly spread the subsequent powder layer on the surface of the sintered layer, thus hindering the smooth development of the SLS process.

Due to the low strength of sintered parts, post-processing is required to achieve high strength, and the three-dimensional parts manufactured generally have problems such as low strength, low precision and poor surface quality. In the early days of SLS, compared with other more mature rapid prototyping methods, selective laser sintering has the advantages of a wide selection of molding materials and a relatively simple molding process. However, since the energy source in the forming process is laser, the application of laser makes the cost of forming equipment high. With the great progress of laser rapid prototyping equipment after 2000, the metallurgical mechanism of complete melting of powder is used for the laser of metal components. Rapid prototyping. Selective Laser Sintering (SLS) has been replaced by similar more advanced technologies.

2.Selective Laser Melting (SLM)

The principle of selective laser melting:

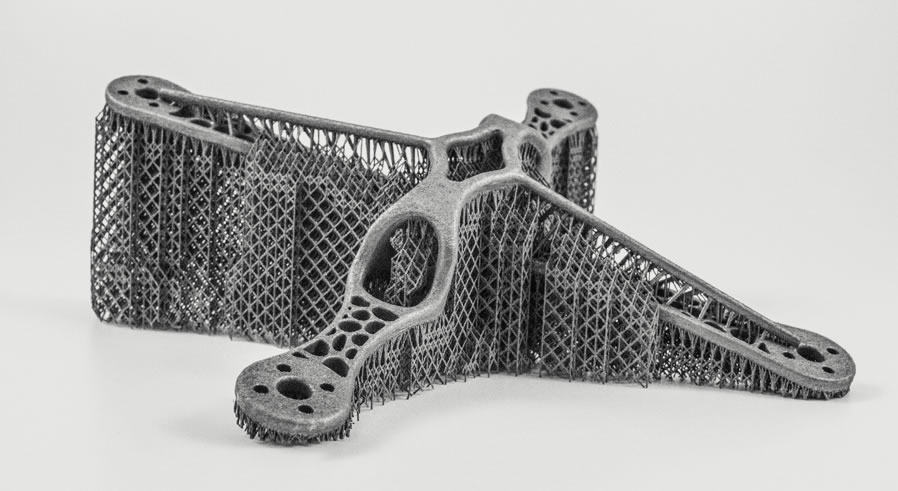

SLM technology is developed on the basis of SLS, and the basic principles of the two are similar. SLM technology needs to completely melt the metal powder and directly form the metal parts, so it requires a high power density laser before the laser beam starts to scan, the horizontal powder roll first spreads the metal powder on the substrate of the processing chamber, and then the laser beam will press the current layer. According to the contour information, the powder on the substrate can be selectively melted to process the contour of the current layer. Then, the lifting system can be lowered by a distance of one layer thickness, and the powder spreading roller can be rolled to spread metal powder on the processed current layer. The equipment adjusts. Enter the next layer for processing, and so on layer by layer until the entire part is processed. The entire processing process is carried out in a vacuum or gas-protected processing chamber to prevent the metal from reacting with other gases at high temperatures.

Advantages of selective laser melting technology

In principle, selective laser melting is similar to selective laser sintering, but because of the use of higher laser energy density and smaller spot diameter, the mechanical properties and dimensional accuracy of the molded parts are better, and only simple post-processing is required. It can be put into use, and the raw materials used for molding do not need special preparation. The advantages of selective laser melting technology can be summarized as follows:

1. Directly manufacture metal functional parts without intermediate processes;

2. With good beam quality, fine focused spots can be obtained, so that functional parts with higher dimensional accuracy and better surface roughness can be directly manufactured;

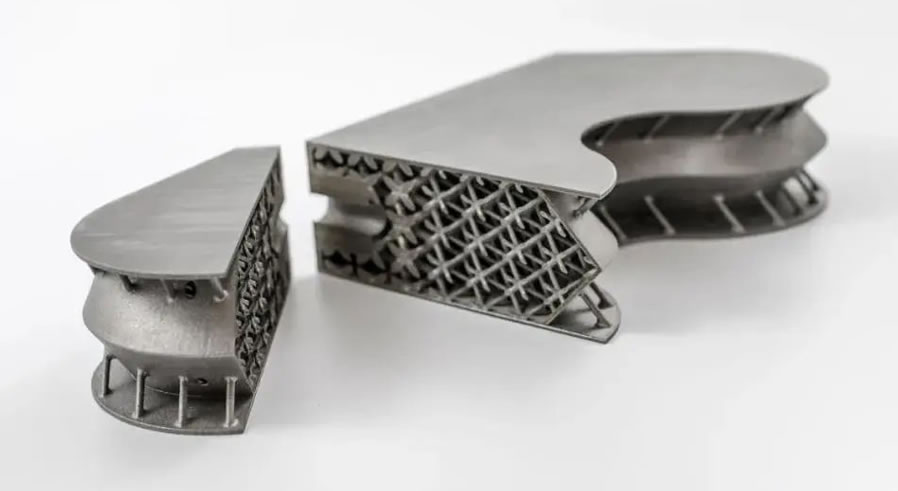

3. The metal powder is completely melted, and the directly manufactured metal functional parts have metallurgical bonding structure, high density, and good mechanical properties, without post-treatment;

4. The powder material can be a single material or a multi-component material, and the raw materials do not need to be specially formulated;

5. Functional parts with complex geometric shapes can be directly manufactured;

6. It is especially suitable for the manufacture of single or small batches of functional parts. The compactness and mechanical properties of selective laser sintering moldings are poor; electron beam melting molding and laser cladding are difficult to obtain parts with high dimensional accuracy; in contrast, selective laser melting molding technology can obtain metallurgical bonding, dense Molded parts with high microstructure, high dimensional accuracy and good mechanical properties are the main research hotspots and development trends of rapid prototyping in recent years.

3.Electron Beam Belting (EBM)

Principle of Electron Beam Selective Melting (EBSM)

Similar to laser selective sintering and laser selective melting processes, electron beam selective melting (EBSM) is a rapid manufacturing technology that uses high-energy, high-speed electron beams to selectively bombard metal powders, thereby melting and forming powder materials. The process of EBSM technology is: first spread a layer of powder on the powder-spreading plane; then, the electron beam is selectively melted according to the information of the cross-sectional profile under the control of the computer, and the metal powder is melted together under the bombardment of the electron beam. , and bond with the formed part below, pile up layer by layer until the whole part is completely melted; finally, remove the excess powder to obtain the desired three-dimensional product.

The real-time scanning signal of the host computer is transmitted to the deflection coil after digital-to-analog conversion and power amplification, and the electron beam is deflected under the action of the magnetic field generated by the corresponding deflection voltage to achieve selective melting. After more than ten years of research, it is found that orthogonal experiments are carried out for some process parameters such as electron beam current, focusing current, action time, powder thickness, accelerating voltage and scanning mode. The action time has the greatest influence on the molding.

Electron beam direct metal forming technology uses high-energy electron beam as processing heat source, scanning and forming can be carried out by manipulating magnetic deflection coil, without mechanical inertia, and the vacuum environment of electron beam can also prevent metal powder from being oxidized during liquid phase sintering or melting . Compared with laser, electron beam has the advantages of high energy utilization rate, large depth of action, high material absorption rate, stability and low operation and maintenance cost. The advantages of EBM technology are high efficiency in the forming process, small deformation of the parts, no metal support in the forming process, denser microstructure, etc. The deflection and focusing control of the electron beam is faster and more sensitive. The deflection of the laser requires the use of a galvanometer, and the rotation speed of the galvanometer is very high when the laser is scanned at high speed. At higher laser powers, the galvo mirror requires a more complex cooling system, and the galvo mirror’s weight increases significantly. Therefore, when scanning with higher power, the scanning speed of the laser will be limited. It is also difficult to quickly change the focal length of the laser when scanning a large forming area. The deflection and focusing of the electron beam is accomplished by using a magnetic field, and the deflection amount and focusing length of the electron beam can be quickly and sensitively controlled by changing the strength and direction of the electrical signal. The electron beam deflection focusing system is not disturbed by metal evaporation. When metal is melted with lasers and electron beams, the metal vapor diffuses throughout the forming space and coats a thin film of metal on any surface it comes in contact with. Electron beam deflection and focusing is done in a magnetic field, so it will not be affected by metal evaporation; optical devices such as laser galvanometers are easily contaminated by evaporation.

4.Laser cladding molding technology (LMD)

Principle of Electron Beam Selective Melting (EBSM)

Laser Metal Deposition (LMD) was first proposed by Sandia National Laboratory in the United States in the 1990s, and subsequently developed in many parts of the world. Since many universities and institutions conduct research independently, this technology There are many names. Although the names are different, their principles are basically the same. During the molding process, the powder is gathered on the working plane through the nozzle, and the laser beam is also gathered to this point, and the powder light action point is coincident. Or the nozzle moves to obtain a piled cladding entity.

The LENS technology uses a kilowatt-level laser. Due to the large laser focusing spot used, generally more than 1mm, although a metallurgically combined dense metal entity can be obtained, its dimensional accuracy and surface finish are not very good, and further machining is required. can be used after processing. Laser cladding is a complex physical and chemical metallurgical process, and the parameters in the cladding process have a great influence on the quality of the cladding parts. The process parameters in laser cladding mainly include laser power, spot diameter, defocusing amount, powder feeding speed, scanning speed, molten pool temperature, etc. Their dilution rate, crack, surface roughness and cladding parts of the cladding layer density has a great impact. At the same time, each parameter also affects each other, which is a very complicated process. Appropriate control methods must be used to control various influencing factors within the allowable range of the cladding process.

5.Direct Metal Laser Forming (DMLS)

There are usually two methods for SLS to manufacture metal parts, one is an indirect method, that is, SLS of polymer-coated metal powder; the other is a direct method, that is, direct metal laser sintering (Direct Metal Laser Sintering, DMLS). Direct sintering of metal powders to form three-dimensional parts using the SLS process has been one of the ultimate goals of rapid prototyping since 1991, when metal powder direct laser sintering research was carried out at the Chatofci University in Leuvne. The main advantage of the DMLS process compared to indirect SLS technology is the elimination of expensive and time-consuming pre- and post-processing steps.

Features of Direct Metal Powder Laser Sintering (DMLS)

As a branch of SLS technology, DMLS technology has basically the same principle. However, DMLS technology is difficult to accurately form metal parts with complex shapes. In the final analysis, it is mainly due to the “spheroidization” effect and sintering deformation of metal powder in DMLS. The spheroidization phenomenon is to make the molten metal surface and surrounding The system formed by the surface of the medium has the minimum free energy. Under the action of the interfacial tension between the liquid metal and the surrounding medium, the shape of the liquid metal surface changes to a spherical surface. Spheroidization will make the metal powder unable to solidify to form a continuous and smooth molten pool after melting, so the formed parts are loose and porous, resulting in failure of molding. Due to the relatively high viscosity of single-component metal powder in the liquid phase sintering stage, “spheroidization” The effect is particularly serious, and the spherical diameter is often larger than the powder particle diameter, which causes a large number of pores to exist in the sintered part. Therefore, the DMLS of single-component metal powder has obvious process defects, and often requires subsequent processing, not in the true sense of ” direct sintering”.

In order to overcome the “spheroidization” phenomenon in single-component metal powder DMLS, and the resulting process defects such as sintering deformation and loose density, it can generally be achieved by using multi-component metal powders with different melting points or using pre-alloyed powders. . The multi-component metal powder system is generally composed of high melting point metal, low melting point metal and some additive elements. The high melting point metal powder is used as the framework metal and can retain its solid core in DMLS; Metals are melted in DMLS to form a liquid phase, and the resulting liquid phase coats, wets and binds the solid-phase metal particles, thereby achieving sintering densification.

3D printing metal materials

According to the type of material, 3D printing metal materials can be divided into iron-based alloys, titanium and titanium-based alloys, nickel-based alloys, cobalt-chromium alloys, aluminum alloys, copper alloys and precious metals.

Our company specializes in providing pure titanium, as well as titanium alloys suitable for 3D metal printing

Titanium and titanium alloys have become ideal materials in the fields of medical equipment, chemical equipment, aerospace and sports equipment due to their remarkable high specific strength, good heat resistance, corrosion resistance, and good biocompatibility. However, titanium alloys are typical difficult-to-machine materials, with high stress, high temperature and severe tool wear during machining, which limit the wide application of titanium alloys. The 3D printing technology is especially suitable for the manufacture of titanium and titanium alloys. First, when 3D printing is in a protective atmosphere, titanium is not easy to react with elements such as oxygen and nitrogen, and the rapid heating and cooling of the micro-area also limits the volatilization of alloying elements; Second, complex shapes can be manufactured without cutting, and based on the high utilization rate of powder or wire materials, there is no waste of raw materials, which greatly reduces the manufacturing cost. At present, the types of 3D printed titanium and titanium alloys include pure Ti, Ti6Al4V (Gr.5) and Ti6Al7Nb, which can be widely used in aerospace parts and artificial implants (such as bones, teeth, etc.).

Ti Gr.1

Titanium alloys have excellent biocompatibility, low stiffness, light weight, high temperature and corrosion resistance, and high ductility. Ideal for medical applications and implants, motor sports, marine, aerospace and aerospace applications.

Applications

Medical Applications and ImplantsApplications where light weight, high temperature and corrosion resistance, and high ductility play an important role:

Aerospace parts

Racing components

Marine parts

Premium Sporting Goods

Ti Gr.5

Ti Gr.5 has high strength, light weight and excellent biocompatibility for technical and medical applications.

Applications

Lightweight, high-strength components for aerospace, sports and marine applications

Medical implant

Medical Tools & Instruments

Dentures

+86 13120915623

+86 13120915623