Properties of Ti-15V-3Cr-3Sn-3Al Rods

| Form | δ or d/mm | Sampling direction | State | Room temperature | ||||||

| σb/MPa | σP0.2/MPa | δ50/% | δ5/% | ψ/% | α/(°) | τ/MPa | ||||

| Rod(Wire) | 2.5~6.5 | L | Solution treatment | 705~945 | - | - | ≥15 | ≥60 | - | ≥550 |

| ST+540℃, 8h, air cooling | ≥1000 | ≥965 | - | ≥10 | ≥25 | - | ≥650 | |||

| ST+520℃, 10h, air cooling | ≥1080 | ≥1010 | - | ≥8 | ≥20 | - | ≥700 | |||

Mechanical properties of Ti-15V-3Cr-3Sn-3Al Rods

| Shear performance of Ti-15V-3Cr-3Sn-3Al Rods | ||||

| Form | d/mm | State | θ/℃ | τ/MPa |

| Rod(Wire) | 3 | 800℃, 15min, air cooling | 20 | 632 |

| 4 | 800℃, 15min, air cooling | 20 | 637 | |

| 6 | 800℃, 15min, air cooling | 20 | 661 | |

| 100 | 520 | |||

| 200 | 500 | |||

| ST+540℃, 8h, air cooling | 20 | 873 | ||

| 100 | 748 | |||

| 200 | 715 | |||

| 300 | 660 | |||

| ST+520℃, 10h, air cooling | 20 | 921 | ||

| 100 | 780 | |||

| 200 | 746 | |||

| 300 | 690 | |||

Elastic properties of Ti-15V-3Cr-3Sn-3Al Rods

| Dynamic elastic modulus | |||||

| Form | d/mm | State | Sampling direction | θ/℃ | Ed/GPa |

| Rod | 14 | 800℃, 30min, water drop | L | 20 | 74.7 |

| 100 | 74.6 | ||||

| 200 | 74.4 | ||||

| 300 | 72.6 | ||||

| 400 | 69.7 | ||||

| Rod | 14 | ST+540℃, 8h, air cooling | L | 20 | 100.6 |

| 100 | 98.3 | ||||

| 200 | 95.1 | ||||

| 300 | 92.3 | ||||

| 400 | 88.3 | ||||

| Shear modulus | |||||

| Form | d/mm | State | Sampling direction | θ/℃ | ED/GPa |

| Rod | 14 | 800℃, 30min, water drop | L | 20 | 30.1 |

| 100 | 30 | ||||

| 200 | 29.6 | ||||

| 300 | 29 | ||||

| 400 | 28.3 | ||||

| Rod | 14 | ST+540℃, 8h, air cooling | L | 20 | 39.1 |

| 100 | 38.1 | ||||

| 200 | 36.8 | ||||

| 300 | 35.6 | ||||

| 400 | 34.1 | ||||

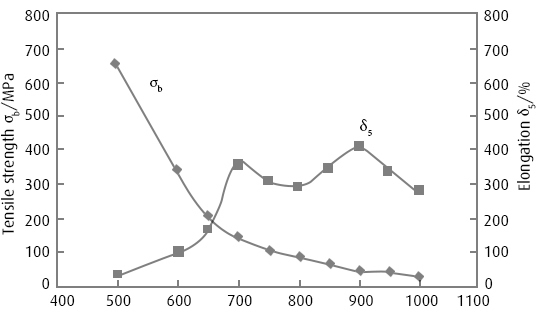

Process plasticity of Ti-15V-3Cr-3Sn-3Al Rods

+86 13120915623

+86 13120915623