Nb50Ti50

Nb50Ti is a superconducting alloy composed of two elements, niobium and titanium. The content of titanium is generally in the range of 46% to 50% (mass fraction). It is one of the most widely used superconducting materials. This alloy has a high superconducting transition temperature and excellent mechanical properties, and is widely used in various fields requiring superconducting properties.

Physical properties of Nb50Ti

• Density: about 7.8g/cm3, the lower density makes it advantageous in some lightweight designs.

• Melting point: about 1427-1454℃, with good high temperature stability.

• Thermal conductivity: about 13.8 W/m·K, higher thermal conductivity helps heat conduction.

• Magnetism: It has certain magnetism and belongs to ferromagnetic materials.

The forms of Nb50Ti50 we provide

Nb50Ti50 Wire

The minimum diameter can reach 0.5mm

Nb50Ti50 Sheet

The technology of using two pure metals, niobium and titanium, to form electrodes in appropriate forms, melting them in a vacuum environment and forming ingots. Both niobium and titanium are active, refractory rare metals, and they can form solid solution alloys with each other. The alloy belongs to the type II superconductor and has a high upper critical field (Hc2). When the niobium-titanium solid solution alloy is treated at low temperature, a pinning phase can be precipitated, giving it a high critical current density.

The molten-cast niobium-titanium alloy has uniform composition and low impurity content.

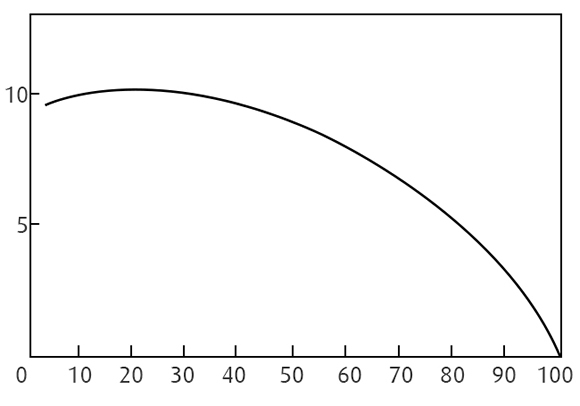

Relationship curve between different titanium contents and critical temperature of niobium-titanium alloy.

Vertical axis: Tc / K

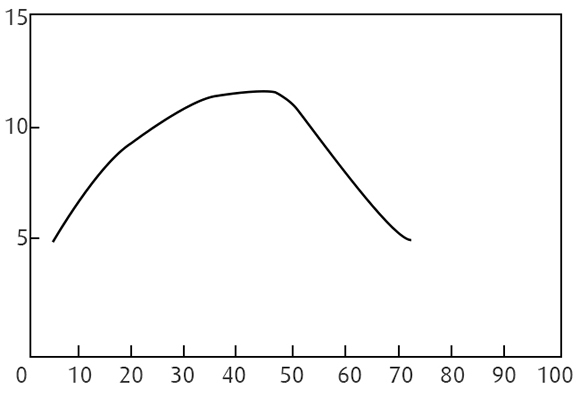

Relationship curve between different titanium contents and upper critical field of niobium-titanium alloy

Vertical axis: Hc2 / T

American niobium-titanium superconducting alloy ingot standards and the impurity content of our niobium-titanium alloy ingots

| Impurities | American NbTi alloy ingot standards | Our NbTi alloy ingot |

| O | ≤1000 | ≤500 |

| H | ≤35 | ≤35 |

| C | ≤100 | ≤100 |

| Fe | ≤50 | ≤125 |

| Ta | ≤1000 | ≤1000 |

| N | ≤100 | ≤100 |

| Ni | ≤100 | ≤50 |

| Si | ≤100 | ≤100 |

| Cu | ≤100 | ≤50 |

| Al | ≤100 | ≤50 |

| Cr | ≤60 | ≤50 |

| Ti content fluctuations | ±1.5% | ±1.5% |

| Hardness(HB) | 148 | 130 |

Application areas of Nb50Ti

Superconducting materials: Due to its excellent superconducting properties, it is widely used in fields requiring superconducting technology, such as magnetic resonance imaging (MRI) equipment, particle accelerators, etc.

High temperature stability: Due to its high temperature stability, it is also used in some environments that require high temperature resistance, such as high temperature superconducting cables.

Lightweight design: Due to its lower density, it is also used in product designs that require lightweight.

+86 13120915623

+86 13120915623