High Purity Aluminium

Usually, pure aluminum with a purity (aluminum content) greater than 99.8% is called high-purity aluminum. It is produced using high-quality refined aluminum as raw material and using directional solidification refining. High-purity aluminum is silver-white, with a smooth surface, clear crystal lines, and no inclusions. High-purity aluminum has properties such as low deformation resistance, high electrical conductivity and good plasticity. It is mainly used in scientific research, electronics industry, chemical industry and manufacturing high-purity alloys, laser materials and some other special purposes.

Physical properties of pure aluminum

| Density(20℃)/kg.m-3 | Melting point /℃ | Specific heat capacity(100℃)/J.(kg.k)-1 | |

| High purity aluminum(99.996%) | 2698 | 660.2 | 934.92 |

| Industrial pure aluminum(99.5%) | 2710 | About 650 | 964.74 |

The chemical composition of High-purity Aluminum

| Grade | chemical composition | |||||||

| Al | Impurities≤ | |||||||

| ≥ | >Fe | Si | Cu | Ga | Mg | Other | Total | |

| Al99.85 | 99.85 | 0.12 | 0.08 | 0.005 | 0.03 | 0.03 | 0.015 | 0.15 |

| Al99.80 | 99.8 | 0.15 | 0.1 | 0.01 | 0.03 | 0.03 | 0.02 | 0.02 |

Forms of High-Purity Aluminum

Our aluminum products include thick plates, thin plates, foils, thick-walled tubes, thin-walled tubes, rods, wires, strips, etc.

Main properties of High-purity Aluminum

High-purity aluminum is a high-tech and high-value-added material, so its main use is in some high-tech fields and scientific research.

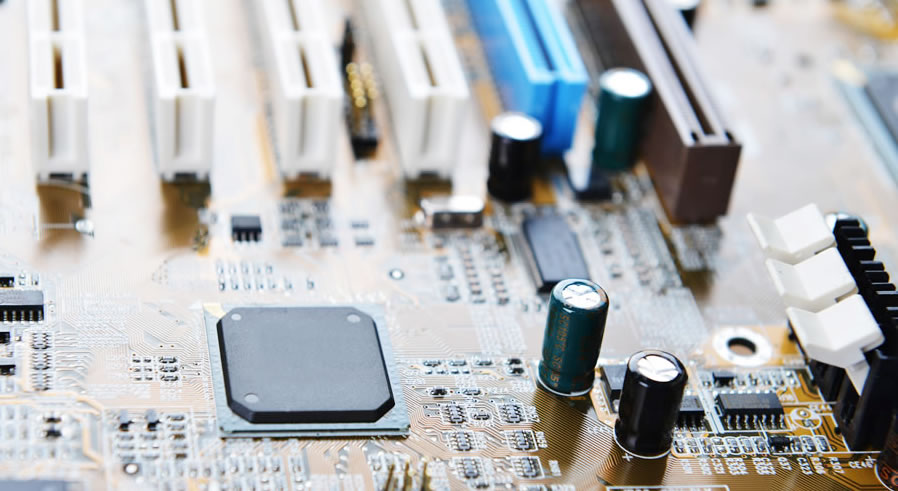

3N~4N aluminum is mainly used to make electrolytic capacitor aluminum foil, which is divided into two types: positive electrode foil and cathode foil. The former uses aluminum with a purity of 3N5~4N8; the latter uses 2N7~3N aluminum or contains trace alloy elements. Low-alloyed aluminum foil such as copper, manganese, etc. Capacitors are widely used in rail vehicles, studiosurge-measuring instruments (studiosurge-measuring instruments, fluorescent lamps and automotive lamps, motorcycle electronic equipment, and film and television equipment.

3N~4N aluminum has an important use in lighting fixtures. The purer the aluminum, the higher the reflectivity to light.

Aerospace vehicles use many aluminum alloys with high strength, high toughness, high creep resistance, and high fatigue resistance. These aluminum alloys must be made of aluminum with low impurity content. The main advantage of using aluminum-containing superalloy single crystals to manufacture turbine engine blades is that it has both extremely high room temperature strength, high high temperature strength and high temperature oxidation resistance, which greatly improves the work of gas generators and hydraulic turbine generators. Performance and efficiency.

5N and 6N high-purity aluminum play an inestimable role in today’s high and new technology. The purer the aluminum used for sputtering, the higher its conductivity.

Another important use of high-purity aluminum is as the wiring of integrated circuits. 5N ultra-pure aluminum is used to manufacture optoelectronic storage media, such as CD, CD-ROM, CD-RW, data disc or mini disc, DVD silver disc, etc.

High-purity aluminum has played an indispensable role in high-energy physics research and detection of elementary particles of matter. For example, the superconducting structure and cables use high-purity aluminum as a stabilizing material for the niobium-titanium (Nb-Ti superconducting wire), so that they are always in a superconducting state.

Application of High-purity Aluminum

Because aluminum has many unique advantages, it has a wide range of uses. Such as transportation industry, construction industry, food packaging industry, home appliance and electronic industry, etc.

+86 13120915623

+86 13120915623