C103

It is a low-strength and high-plasticity alloy. Compared with other refractory metal alloys, it has higher specific strength (strength/density), excellent plasticity, processing and welding properties. At the same time, it also has a small thermal neutron absorption cross section, resistance to liquid metal corrosion and excellent superconductivity. It is regarded as one of the most promising high-temperature materials.

| Mechanical properties of C103(Nb-10Hf-1Ti)(21℃) | ||||

| Grade | Elastic Modulus/MPa | Tensile Strength/MPa | Yield Strength/MPa | Elongation (Gauge Length 50.8mm)/% |

| C-103 | 112490 | 428.9 | 295.3 | 20 |

Physical properties of C103

| Grade | Component | Density /g.cm-3 | Melting point /℃ |

Linear expansion coefficient /10-6K-1 |

Recrystallization temperature /℃ |

Annealing temperature /℃ |

Elongation brittle transition temperature /℃ |

| C103 | Nb-10Hf-1Ti-0.7Zr-0.1W-0.1Mo-0.05Ta | 8.86 | 2349 | 4.5(1203℃) | 1038~1316 | 871 | -196 |

Main chemical composition of C103 (mass fraction)

| Grade | Chemical Composition / % | Chemical Composition / 10-6 |

|||||||||

| Nb | W | Mo | Ta | V | Hf | Zr | Ti | C | O | N | |

| C103 Nb-10Hf-1Ti | Balance | 9~11 | <0.7 | 0.7~1.3 | <100 | <300 | <300 | ||||

Forms of C103 We Can Provide

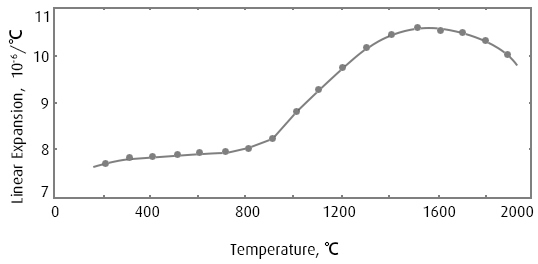

Linear Expansion and Conductivity C103(Nb-10Hf-1Ti)

Linear Expansion of C103

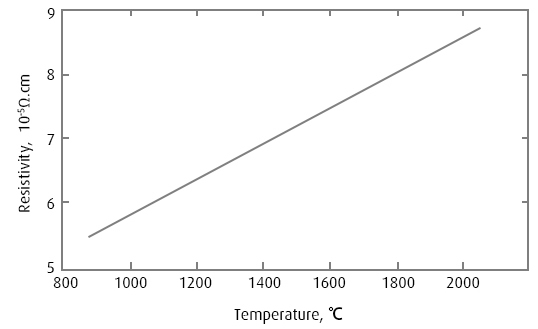

Resistivity of C103

| Resistivity of C103(Nb-10Hf-1Ti) | |||||||||||

| Temperature,℃ | 900 | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | 1600 | 1700 | 1800 | 1900 |

| ε | 0.33 | 0.32 | 0.31 | 0.29 | 0.28 | 0.26 | 0.26 | 0.26 | 0.27 | 0.27 | 0.27 |

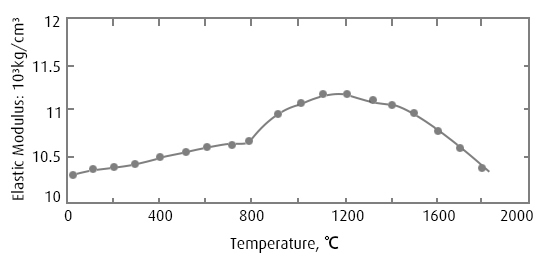

Elastic Modulus and high temperature tensile properties of C103(Nb-10Hf-1Ti)

Elastic modulus of C103

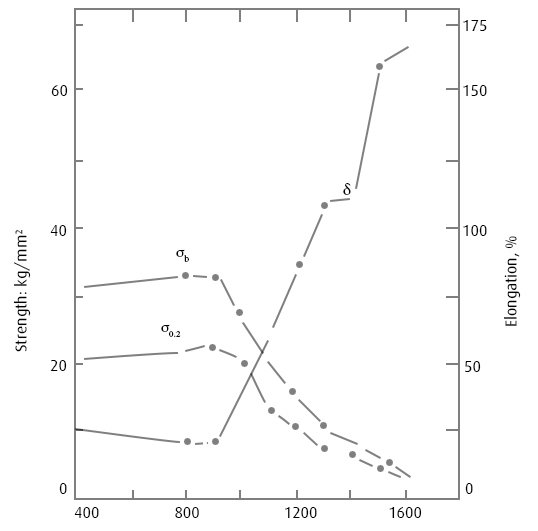

High temperature tensile properties(annealed at 1200℃) of C103

| High temperature performance of C103(Nb-10Hf-1Ti) | ||||||

| Grade | Component | Forms | Temperature/℃ | Tensile Strength/MPa | Temperature/℃ | Breaking Strength/MPa |

| C-103 | 10Hf、1Ti、0.7Zr | Sheet | 1093 | 189.8 | - | - |

Applications of C103

High temperature and high strength, it is used as structural material of space shuttle engine and rocket nozzle, heat exchange tube of jet aircraft, etc.

+86 13120915623

+86 13120915623