Features of Powder Products for 3D Printing

Spherical 3D printing powder features: high fluidity, low oxygen content, high vibration density and low cost.

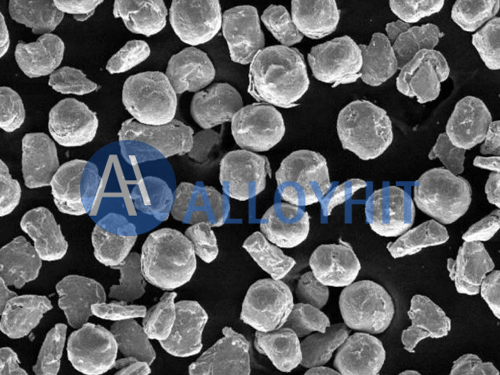

Spherical MIN titanium injection molding powder features: moderate particle size to ensure the vibrating density of the blank; Good fluidity ensures small feeding resistance in injection molding; The quasi spherical shape ensures small sintering deformation, controllable forming and improves the qualified rate of products; High vibration density improves the relative density of sintered parts and is easy to polish; The low oxygen content ensures the mechanical properties of the product; The controllable hydrogen content can realize appropriate shrinkage, and the powder is easier to form; Low manufacturing cost.

Specifications for Powder Products for 3D Printing

| Spherical like powder for 3D printing and MIM injection molding | ||||||||||||

| Specifications | Current Speed | Particle size distribution | Maximum Impurity Element Content (%) | |||||||||

| D10 | D50 | D90 | Al | V | Fe | C | N | H | O | |||

| MIM Titanium powder | 0-55μm | 65S | 8 | 30 | 53 | 5.5-6.5 | 3.5-4.5 | 0.2 | 0.05 | 0.03 | 0.02 | 0.17 |

| 3D printing powder | 15-55μm | 55S | 17 | 32 | 56 | 5.5-6.5 | 3.5-4.5 | 0.2 | 0.05 | 0.03 | 0.02 | 0.15 |

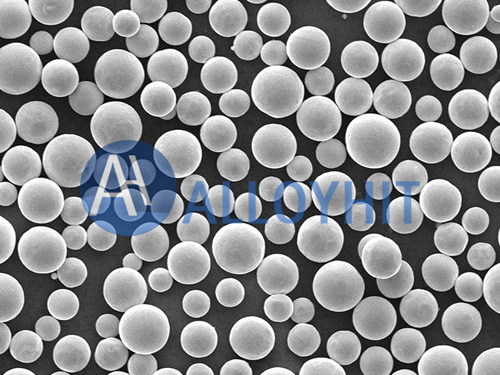

| 3D printing spherical powder | ||||||||||||

| Specifications | Current Speed | Particle size distribution | Maximum Impurity Element Content (%) | |||||||||

| D10 | D50 | D90 | Al | V | Fe | C | N | H | O | |||

| Pure titanium 3D printing powder | 15-53μm | 42S | 15 | 30 | 54 | 0 | 0 | 0.18 | 0.03 | 0.03 | 0.02 | 0.13 |

| Ti-6Al-4V 3D printing powder | 15-53μm | 42S | 16 | 31 | 55 | 5.5-6.5 | 3.5-4.5 | 0.18 | 0.03 | 0.03 | 0.02 | 0.13 |

Particle size distribution curve of Powder Products for 3D Printing

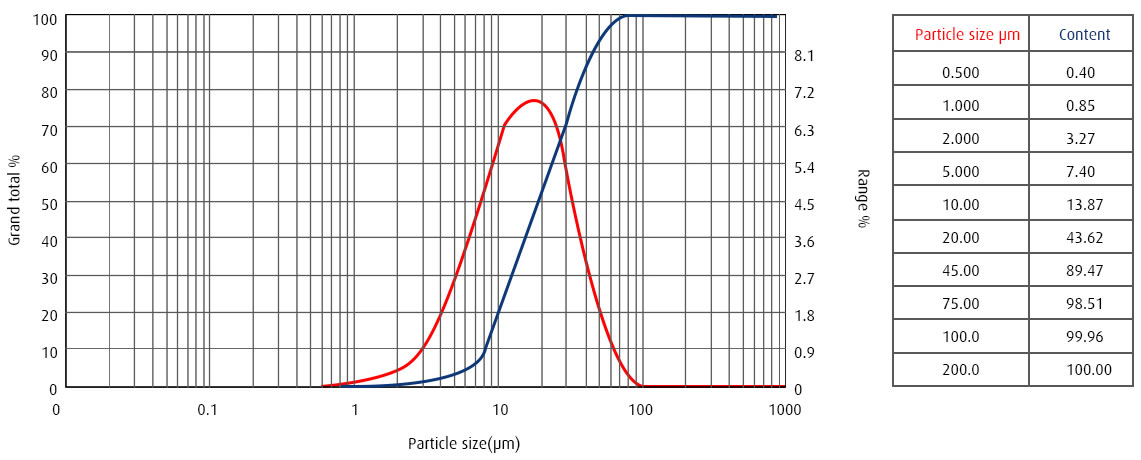

Particle size distribution curve of spherical MIM titanium injection molding powder

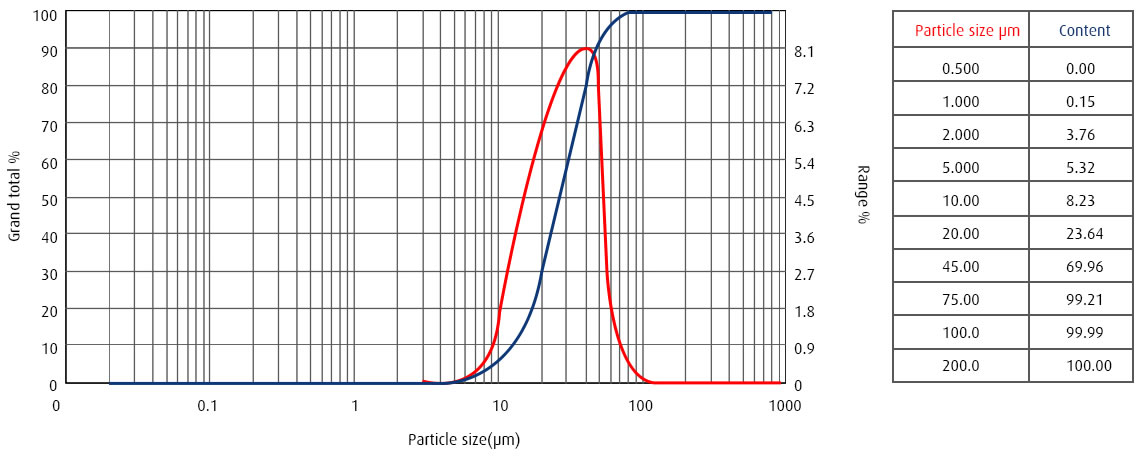

Particle size distribution curve of spherical like 3D printing powder

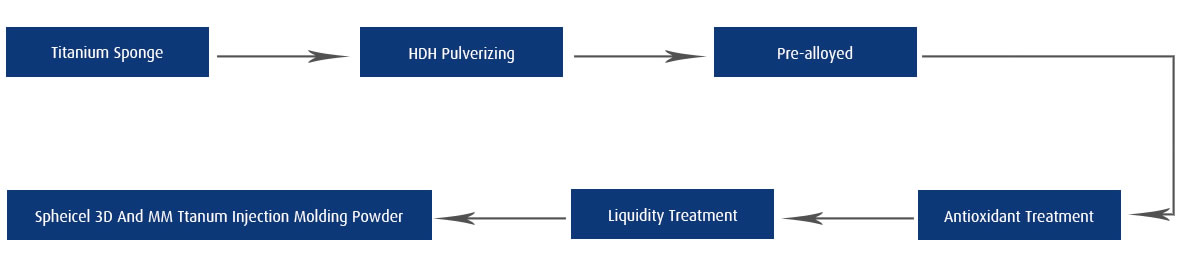

Production Process of Powder Products for 3D Printing

+86 13120915623

+86 13120915623