Nb-1Zr

Niobium-zirconium alloy refers to an alloy composed of metallic zirconium added to metallic niobium. The most important Niobium-zirconium alloy is Nb-1Zr alloy.

Zirconium exists mainly in the form of solid solution in niobium alloys. When there are trace amounts of oxygen and carbon, or when trace amounts of carbon are added, a small amount of carbides and oxides are dispersed and precipitated. Adding zirconium to niobium can increase the strength of the alloy without affecting the plasticity and processing properties of the alloy. Zirconium can also improve the alloy’s oxidation resistance and alkali metal corrosion resistance.

Chemical composition of Nb-1Zr

| Main Elements | Impurity elements, not more than | |||||||||||

| Nb | Zr | Ti | C | O | H | Ta | Fe | Si | W | Ni | Mo | |

| Nb-1Zr | Balance | 0.8~1.2 | 0.02 | 0.01 | 0.015 | 0.0015 | 0.1 | 0.005 | 0.005 | 0.03 | 0.005 | 0.01 |

Mechanical properties of Nb-1Zr

| Tensile Strength | Yield Strength | Elongation | |

| Nb-1Zr | ≥195 | ≥125 | ≥20 |

The forms of Nb-1Zr we provide

Nb-1Zr Sheet

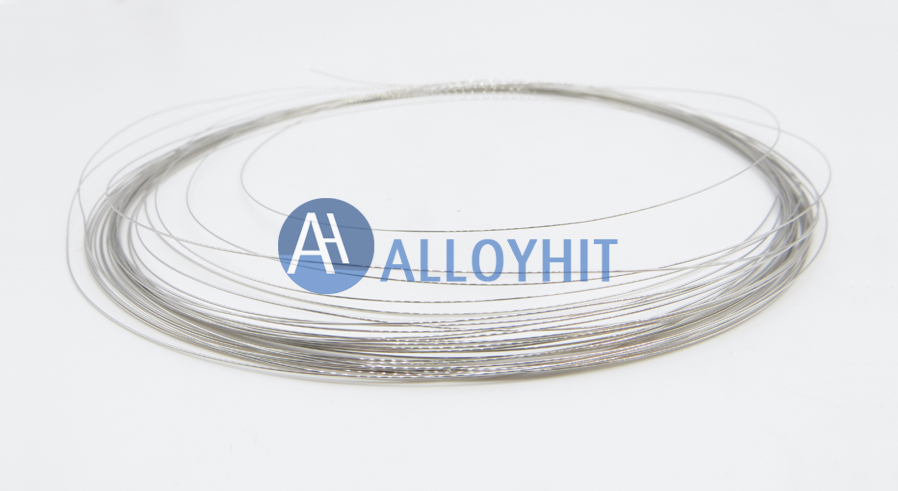

Nb-1Zr Wire

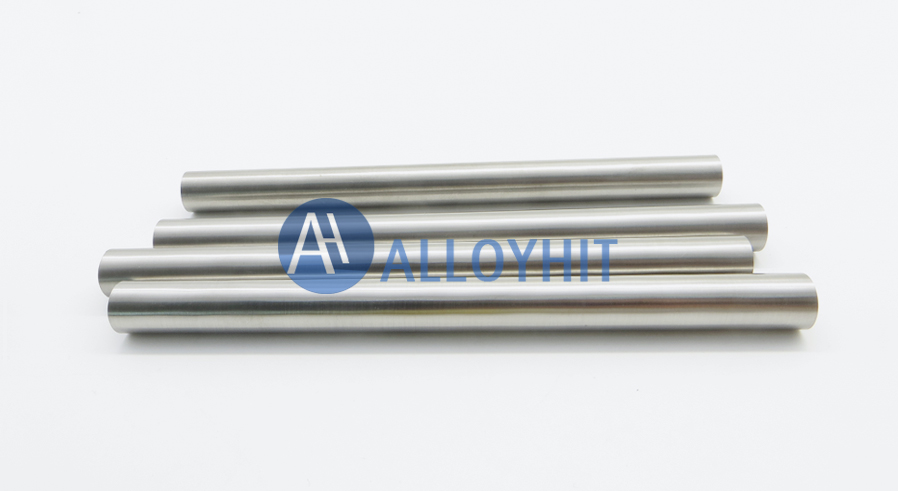

Nb-1Zr Rod

Nb-1Zr Part

Preparation method of Nb-1Zr

According to the requirements for its performance and the purity of interstitial impurities (carbon, oxygen, nitrogen) during use, Nb-1Zr alloy is produced by a consumable arc furnace, electron beam furnace or a combination of the two to produce alloy ingots.

For products with lower purity requirements, they can also be pressed and sintered into alloy ingots by mixing niobium powder and zirconium powder.

Processing process of Nb-1Zr

The smelted alloy ingots need to be hot extruded or hot forged to form blanks, and then processed by forging, rolling, etc. to make various profiles.

Powder sintered ingots can be directly processed into materials.

Applications of Nb-1Zr

Nb-1Zr alloy is the most widely used niobium alloy. It is a low-strength niobium alloy with good processing and welding performance. It is mainly used in aerospace, atomic reactors, new electric light source sodium lamps and other application fields, such as structural materials of aircraft engines and rocket nozzles, original parts and sheath materials in reactors, and various corrosion-resistant parts resistant to nitric acid, hydrochloric acid or sulfuric acid corrosion conditions, and used for anode leads of electrolytic capacitors of high-pressure sodium lamps.

+86 13120915623

+86 13120915623